Rohre Valves

German High Class Industrial Valves

Deutsche Industriearmaturen der Spitzenklasse

Rohre Valves

German High Class Industrial Valves

Deutsche Industriearmaturen der Spitzenklasse

Rohre Valves supplied successfully Motor Operated Valves with Duplex Stainless Steel A995 5A material to Power and Water Utillity Company for Jubail and Yanbu - MARAFIQ.

these valves that actuated with Rotork actuators, used for replacement of SWC Plant-1 Drum Screen System & LCP in Plant-2 Jubail.

Rohre Valves specializes in high-performance ball control valves engineered for precise regulation, reliable shut-off, and durable operation in demanding industrial processes. Our products are designed for applications where accurate flow control, high pressure tolerance, and minimal maintenance are critical.

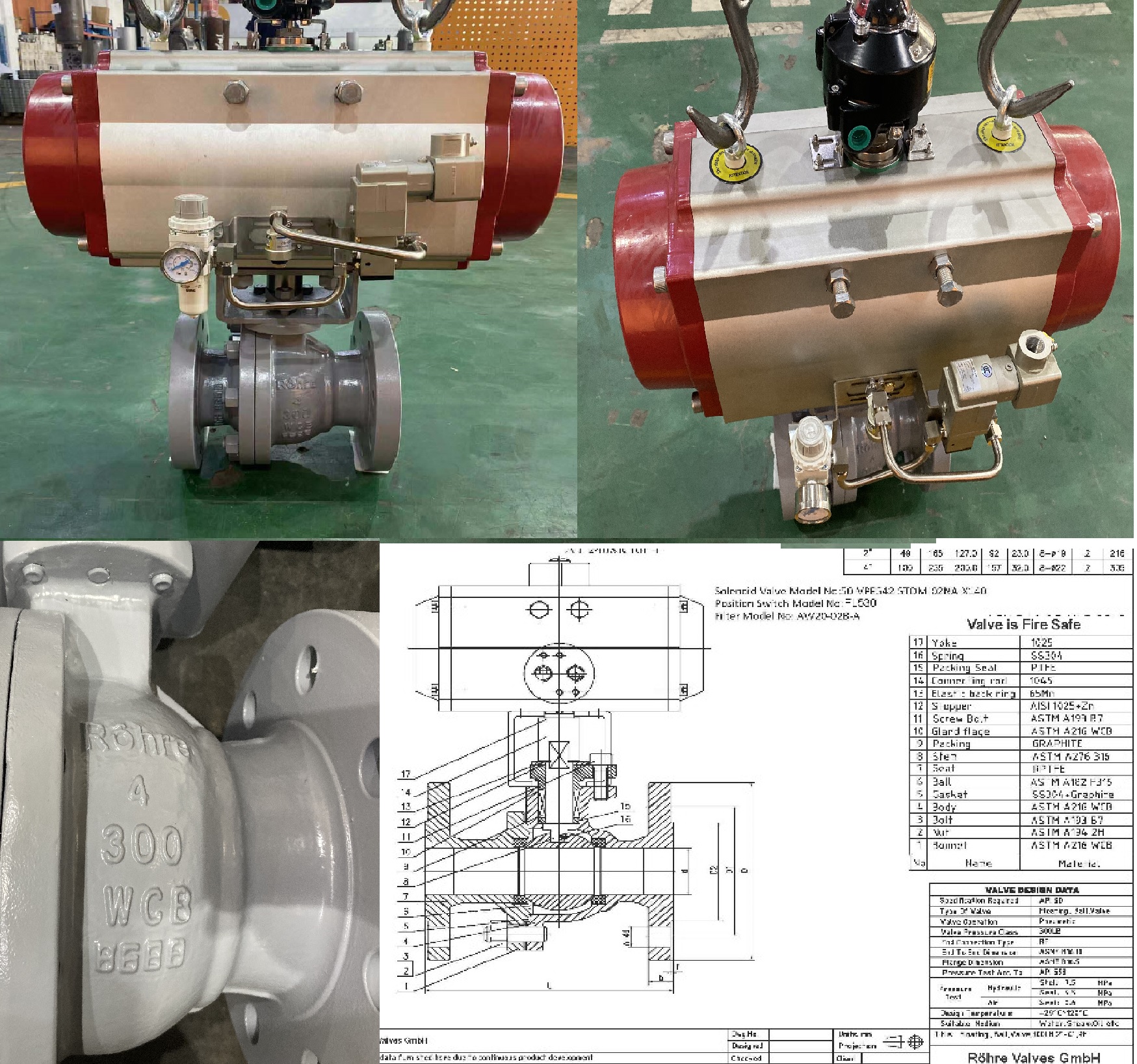

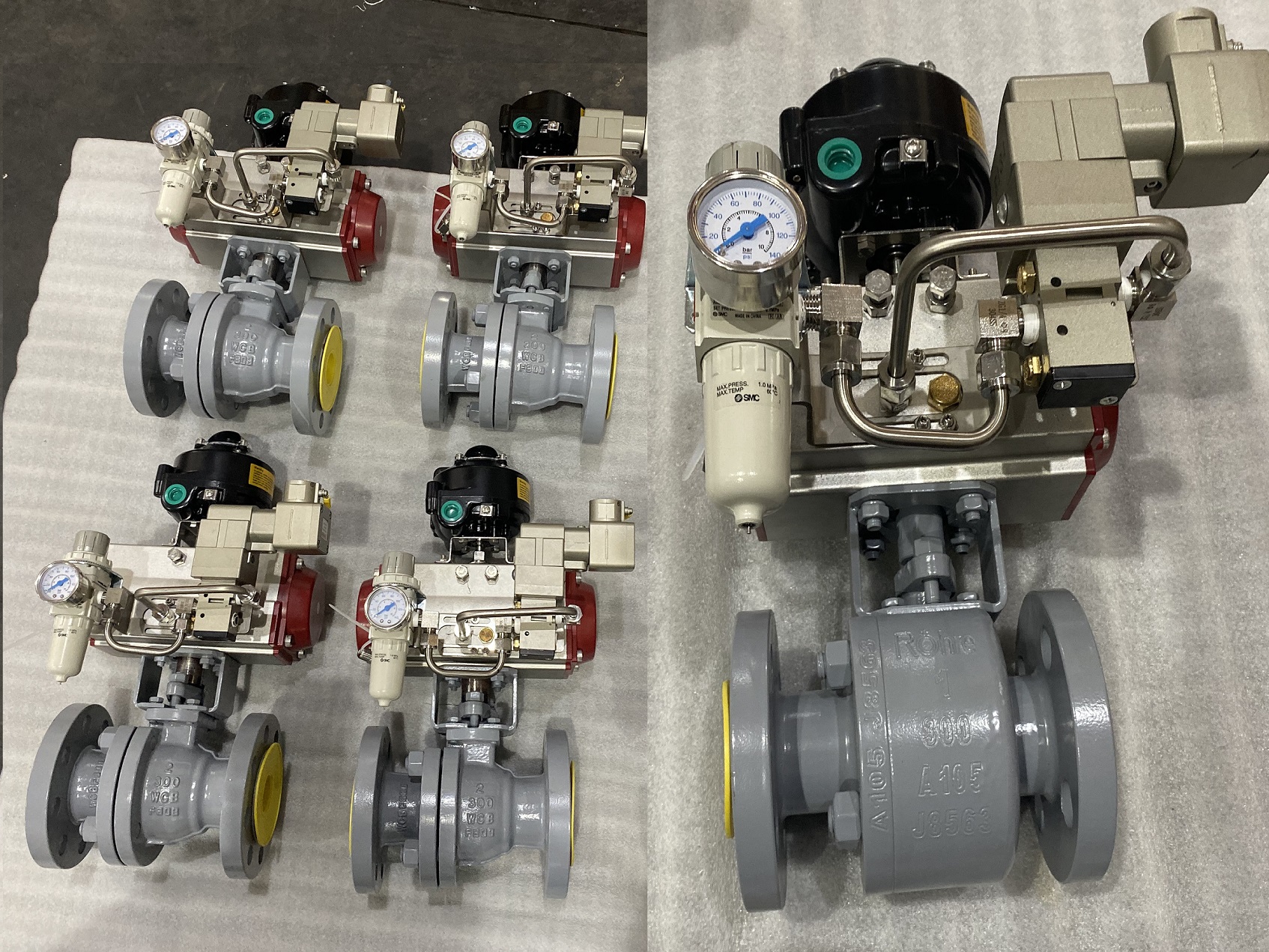

Key Features & Technical Specifications: Valve Type: Ball Control Valve (Characterized / V-Port Ball) Primary Function: Precise modulating control and tight shut-off Design: Typically features a characterized V-port or segmented ball, which provides a precise equal percentage flow characteristic for excellent control over a wide range of flows. Pressure Rating: Available in a range of classes (e.g., ANSI Class 150 to 2500, PN 16 to PN 420) to suit various system pressures. Temperature Range: Engineered to handle extreme temperatures, from cryogenic applications to high-temperature steam and process fluids, depending on seat and seal materials. Materials of Construction: Body: Carbon Steel (A216 WCB), Stainless Steel (CF8M, CF8), Duplex Stainless Steel, Alloy 20, and other exotic alloys. Ball & Stem: Typically 316 Stainless Steel, often with hard coatings (e.g., Stellite, Chrome Carbide) for wear and erosion resistance. Seats: Reinforced PTFE, PEEK, Metal-Seated, or other advanced polymers to ensure tight shut-off and long service life. Actuation: Compatible with pneumatic, electric, and hydraulic actuators. Can be equipped with positioners and other accessories for integration into automated control systems.

Rohre Valves specializes in Automatic Recirculation Control (ARC) Valve, Automatic Recirculation Control Valve is a specialized, multi-functional valve designed to protect centrifugal pumps from damage caused by low flow operation

Instead of needing a separate complex system of valves and controls, an ARC valve combines everything into one unit. It performs four key functions automatically, without any external power When the main process doesn't need much flow, the ARC valve ensures that a minimum, safe amount of flow is always maintained through the pump by automatically recirculating it, thus preventing overheating and damage. Temperature Range: Engineered to handle extreme temperatures, from cryogenic applications to high-temperature steam and process fluids, depending on seat and seal materials. ARC valves are essential in any application where pump flow can vary significantly and pumps must be protected. Common industries include: Power Generation: Boiler feedwater pumps. Oil & Gas: Pipeline transfer pumps, charge pumps in refineries. Chemical & Process Industries: Any critical centrifugal pump where flow demand fluctuates.

Pressure Seal Globe Valves Market Insights and Global Outlook During 2019-2025 : Rohre

MarketInsightsReports has published a report entitled Global Pressure Seal Globe Valves Market Research Report 2019 that is a detailed observation of several aspects, including the rate of growth, technological advances and various strategies implemented by the main current market players. The report is based on a collective analysis of data, which is obtained through primary and secondary research. It provides a systematic approach to the current and prospective scenario of this market.The pressure seal globe valves are designed in accordance with BS1873 and ASME B16.34 for service of high temperature and high pressure and are widely used in fossil fuel power plant.